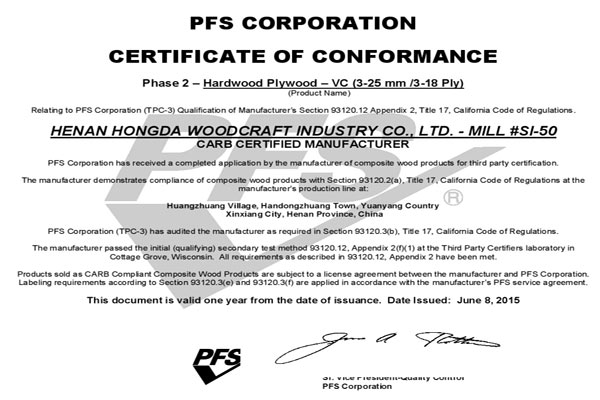

Congratulations to the Henan HTC wood industry limited company through CARB certification America

Congratulations to the Henan HTC wood industry limited company through CARB certification America Henan Hongda Wood Co., Ltd. is the national poverty alleviation leading enterprises, national large man-made board production enterprises, covers an area of more than 360 acres, total assets of 3.6 billion yuan, with 20 domestic most advanced wood-based panel production line. The company insists on self planting forest, concentrate on high quality man-made board, and not make a harmful wood.. Hongda wood has a million acres of sheet material planting base, 20 years experience in production of sheet, the top technical talent in the domestic first-class production equipment and industry has passed 3C certification, 3 standard certification, occupational health and safety management system certification and U. S. carb certification, and has import and export operation rights.

Henan Hongda wood production of high-grade wood-based panel series plate, using domestic advanced equipment and advanced technology, high-quality imported materials, environment-friendly glue, after repeated processing, light brand products with characteristics of green, environmental protection, avoid lacquer, waterproof, non formaldehyde etc., suitable for luxury train and bus interior, high-grade furniture, etc..

Intensity card, Lin Zhiguang card multi-layer solid wood plate, free paint ecological board and poplar plywood, furniture and other decorative plate, melamine stick panel, poplar wood Daixinban, high-grade poplar wood wardrobe cabinets board, star rated hotels decoration board, high-grade blockboard, bus interior plywood products with its green advantages, sold domestically and exported to the United States, Canada, Japan, Mexico, more than 20 countries and regions, light plate, Lin Zhiguang plate depending on the characteristics of the excellent product performance and green environmental protection, foreign praise and trust.

The main types of the whole cabinet, wardrobe sheet and choose standard

The main types of the whole cabinet, wardrobe sheet and choose standard A, sheet

Plate is the main material of integral ambry wardrobe, which directlydetermines the product quality. Cabinet plate on the market mainly usesman-made board, rarely used wood. Artificial board is divided into splint(also called multilayer board), particle board, fiberboard. The fiber boardand high density, medium density, low density of.

1, high density board: it is made of wood fiber or other plant fiber as raw material, after cooking and ground into a fine fiber by adding an appropriate amount of adhesive, at a certain temperature and pressure pressed. High density, high strength.

2, particle board: namely the proverb "board", the wood into small particles of wood shavings and adding proper amount of adhesive agent, under certain temperature and pressure pressed. Density is not high, intensity.

3, the multi-layer solid wood board: the wood adhesive layers of singleplates or sheets after the cold pressing, hot pressing, sanding, health and several working procedure produced. With a small modification, high strength, good internal quality (cut saw after the small, non hierarchicalpores), characteristics such as good flatness. As is currently the Handmadefurniture with excellent performance is not easy to deform and good adjusting indoor temperature and humidity of the multi-layer solid woodboard (wardrobe cabinets etc.) is the most commonly used materials. Is thematerial the highest price on the market.

4, melamine board: the melamine impregnated paper is directly pressed on the particleboard and multi-layer solid wood board (the acronym: multi-layerecological board). The multi-layer ecological plate has gradually become the main material most wardrobe cabinets manufacturers.

Criterion two, plate quality

1, look at the cabinet plate adopts a multilayer board or particieboard,judgment method is from the plate of view, multilayer board has a layer ofskin plastic pressure formed multilayer board, smooth surface, good not easy deformation, strong grip nails. Long service life; and particleboard fine particle structure closely enough, even can see the small pores, placed in the hands of the lighter weight, small, short service life.

2, to see whether meet environmental protection sheet. As long as the free formaldehyde content ≤ 9mg/100g board in the European E1 class environmental standards, to human body health not harm. The most direct way is to open the door, open the drawers, if strongly stimulate smell, evenmake people cry, show that formaldehyde content exceed the standard; two is to look at the material inspection certificate business, to see whether it isholding the inspection certificate of quality national imitation board testingcenter.

3 see plank is real. Currently on the market some small manufacturers in order to reduce costs, often cheat, deceive consumers. Standard cabinetbody plate thickness is 18mm, and small manufacturers generally use themeans with particleboard when high density board to propaganda,thickness is 16mm, and for consumers said its board for 18mm. And the back plate thickness of 9mm, door thickness is 9mm.

Congratulations to hongda wood industry co., LTD., was awarded the mayor of xinxiang, henan quality prize On January 2, 2014, xinxiang accelerate national quality demonstration cities create and mayor of strong quality prize award ceremony. Meeting to henan hongda wood industry co., LTD., and other five units issued by the mayor's award for 2013. Municipal leaders wang bench, Wang Zhitong, high through the line, Liu Sen, qin to attend the conference. Mayor wang bench requirement, the city's various departments at all levels should be solidarity and collaboration, difficult to overcome, strive to create success at a stroke, constantly enhance the level of quality work.

Congratulations to hongda wood industry co., LTD., was awarded the mayor of xinxiang, henan quality prize On January 2, 2014, xinxiang accelerate national quality demonstration cities create and mayor of strong quality prize award ceremony. Meeting to henan hongda wood industry co., LTD., and other five units issued by the mayor's award for 2013. Municipal leaders wang bench, Wang Zhitong, high through the line, Liu Sen, qin to attend the conference. Mayor wang bench requirement, the city's various departments at all levels should be solidarity and collaboration, difficult to overcome, strive to create success at a stroke, constantly enhance the level of quality work.  Man-made board products are mainly adhesive is introduced In plywood products manufacturing process, the glue is essential factors of production, the quality of the glue is the top priority in the process of production, it is not only relation with the quality of our products and more relationship with physical health, but most people within the plywood products on the performance of the commonly used plastic etc also don't know, here are the henan hongda wood industry co., LTD. Web site under the small make up a simple introduction for everybody plywood products commonly used the knowledge of the glue, the following content is collected via baidu entry, please forgive me if there is an unknown.

Man-made board products are mainly adhesive is introduced In plywood products manufacturing process, the glue is essential factors of production, the quality of the glue is the top priority in the process of production, it is not only relation with the quality of our products and more relationship with physical health, but most people within the plywood products on the performance of the commonly used plastic etc also don't know, here are the henan hongda wood industry co., LTD. Web site under the small make up a simple introduction for everybody plywood products commonly used the knowledge of the glue, the following content is collected via baidu entry, please forgive me if there is an unknown.  A whole wardrobe production process of the components and main process The next few years domestic whole wardrobe factory there will be two main production: one is the large-scale production of the enterprise business investment in place at a time, advanced production equipment, high market share, capital is abundant, the production is large, process will be more complicated; Another is some small and medium-sized enterprises in order to survive or attached to large companies or their combined to enhance competitiveness, to form a joint production situation, production process will be more detailed, there will be a process production enterprises, such as cutting can be single independent factory, will be the joint venture of sheet metal processing, such as some factory to do the paint again, or a product parts and components, in order to improve the efficiency of production equipment. Both the former and the latter for product process design will be more and more clear, more and more perfect, to achieve highly harmonious and unified, so as to match the operation. Then there is the computer with the popularization and application of LAN, the process flow field management will be no technology file management, are all made of bar code management, production management will be more convenient, faster and more accurate.

A whole wardrobe production process of the components and main process The next few years domestic whole wardrobe factory there will be two main production: one is the large-scale production of the enterprise business investment in place at a time, advanced production equipment, high market share, capital is abundant, the production is large, process will be more complicated; Another is some small and medium-sized enterprises in order to survive or attached to large companies or their combined to enhance competitiveness, to form a joint production situation, production process will be more detailed, there will be a process production enterprises, such as cutting can be single independent factory, will be the joint venture of sheet metal processing, such as some factory to do the paint again, or a product parts and components, in order to improve the efficiency of production equipment. Both the former and the latter for product process design will be more and more clear, more and more perfect, to achieve highly harmonious and unified, so as to match the operation. Then there is the computer with the popularization and application of LAN, the process flow field management will be no technology file management, are all made of bar code management, production management will be more convenient, faster and more accurate.  What furniture plate do good? Panel of knowledge and plank of choice

What furniture plate do good? Panel of knowledge and plank of choice  Henan hongda wood industry co., LTD. Is a national poverty alleviation leading enterprise, national large-scale man-made board production enterprise.

The compa...More

Henan hongda wood industry co., LTD. Is a national poverty alleviation leading enterprise, national large-scale man-made board production enterprise.

The compa...More